Strange Engineering Logic

Yesterday, I was in the computer lab doing my Computer Aided Design (CAD). After I asked the professor to vet through my assignment so as to declare it as done, this interesting conversation took place...

[After some discussion and grading of Glass Cookie's CAD assignment for the day...]

Prof: So, are you Singaporean, or are you Indonesian?

GC (somewhat taken aback at the abrupt switching of topics, but later convinced himself that he should get used to such a question, considering its frequency): Erm...

GC's thoughts (interrupting within a few seconds): Hmmm, looks like it's another +1 to the Indonesian category [Fyi, GC's nationality/race has usually been mistaken to be one of the following (all but Singaporean, sadly): Indonesian, Korean, Japanese, Hong Konger, Eurasion... etc.]

GC (continuing, after a short pause after GC's thoughts interrupted): I'm... Singaporean? [well, GC didn't exactly retort back a question. Rather, it was more like his expression was such that he tried to convey a question about how the prof came with that conclusion]

Prof: Oh, I see. You see, because I don't hear any singlish coming from you, I thought you're probably Indonesian or something.

GC's thoughts: Huh? That's... new...

GC (trying not too reveal that it felt/seemed/'logic-ed' strange to him): Oh, OK.

And with the above taking place, perhaps to establish my nationality, I should consider asking him in this manner, "Eh... prof, you know hor, I finish this question already leh. So, you come see and mark, can? See got anything wrong or not? Thank you ah..."

And of course, just in case you thought that the engineering prof who was there in the lab had some strange logic, well, that's not exactly the main gist of this post. Well, if you noticed at the start of the post, I mentioned that I was doing CAD (ie. usage of computers to create 3d models for prototyping). That was actually one out of three modules that I have to do for this crappy school term in order to come up with a physical "engineering innovative design" (EID - the name of this crazy project) prototype. The other two modules are Computational Fluid Dynamics (CFD, using computers to solve for aerodynamic flows over an object) and Non-Destructive Testing (NDT, techniques used to scan for cracks without having to damage the component being tested, through surface dyes, x-rays, ultrasonics... etc). And yup, for 5 whole weeks (OK, maybe not 5 whole weeks considering that I have an audition at the end of this month. Perhaps 5 days less of 5 weeks), I have to be in school to go through these 3 modules and meet with my group to discuss as to how to create some prototype of some sort, which in my opinion, is a total waste of time and exploitation of students. Hmmm, just in case I end up talking about my grievances instead of the original intended content of this post, I'd better get back to the topic...

As I was saying (or rather, typing), considering that my group came up with the idea of improving the current powder dispensing machine for drinks, and that the three modules have got to be applicable (I mean, why else would they teach something totally unrelated and non-applicable to students for this EID project, right?), I tried to reason the rationale of having these 3 modules. And after some thought with the help of the crappy side of me, I came up with the following flow of thoughts/conclusions:

- These three courses must be applicable considering that those big guys at the top, being part of engineering college and hence deduced as logical people supposedly, decided upon them.

- In engineering, I have been thought that the stages of design are: concept, design (CAD), analysis of design (CFD), and then the prototyping. In aer*space, maintenance is also required, and detection of defects for maintenance is done via NDT.

- The only possibility of these 3 modules applicable and used is such that: 1) The dispensing machine would be modeled with the help of computers using CAD. 2) Following that, analysis of the aerodynamics and performance of the dispensing machine at around Mach 1 or beyond would be done with the help of computers (considering that I was taught turbulent flow in CFD and you need high enough a velocity to reach turbulent flow). 3) After all that is done, we take the prototype and send it flying at that kind of speed to test the accuracy of the CFD analysis. 4) Finally, NDT is used to test for any cracks or defects that might have occured due to the harsh conditions experienced by the prototype.

Thought: I hope the poor dispensing machine would be able to last its maiden voyage...

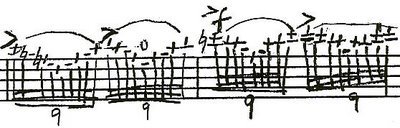

Well, since strings sound somewhat soft, and somewhat muffled such that demisemiquavers are not to distinct, and considering it does take up time and there are 5 other pieces to go, and considering this is but 2 bars in a 100 bar piece, and considering blah blah blah... sometimes I play just a note. (OK, most of the time, happy?) Hey, I'm not the only keyboardist around guilty right? Someone tell me I'm not the only one... pleeeese....

Well, since strings sound somewhat soft, and somewhat muffled such that demisemiquavers are not to distinct, and considering it does take up time and there are 5 other pieces to go, and considering this is but 2 bars in a 100 bar piece, and considering blah blah blah... sometimes I play just a note. (OK, most of the time, happy?) Hey, I'm not the only keyboardist around guilty right? Someone tell me I'm not the only one... pleeeese....

0 Comments:

Post a Comment

<< Home